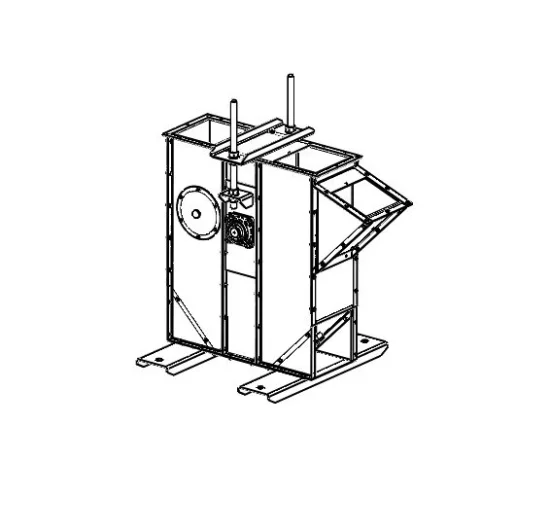

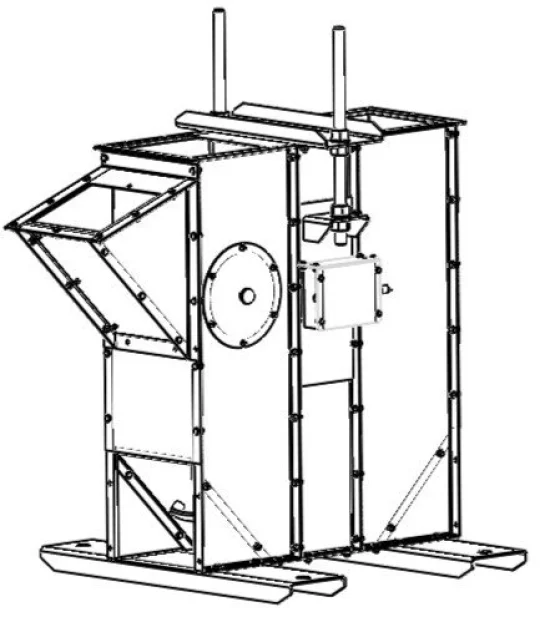

The boot section (tensioning station) of the bucket elevator is a bolted structure made from galvanized sheet steel. Belt tensioning is achieved by tightening two tensioning screws, which advance the tensioning drum (pulley) forward. The tensioning drum features a special design that prevents material buildup, ensuring uninterrupted belt movement. It is mounted on a tensioning shaft, supported by two self-aligning bearings installed on adjustable mounting plates. An optional rotation monitoring sensor can be installed on the shaft. The sensor detects changes in shaft speed due to belt slack, breakage, elevator blockage, or other malfunctions and triggers an emergency stop of the machine. Material intake occurs through a dedicated inlet pocket, which is mounted either at the front or rear side of the boot, depending on the specific installation configuration. |