|

|

|

|

Floor Ventilation – Key Element in Grain Storage

Floor ventilation is a crucial component for proper grain storage in both silos and flat warehouses.

It is considered the most effective method for ventilating grain and bulk products.

System Overview:

-

Consists of channels embedded in the concrete foundation of the silo or warehouse floor

-

Channels are interconnected and covered with ventilation planks featuring special construction and perforation for maximum airflow and cooling

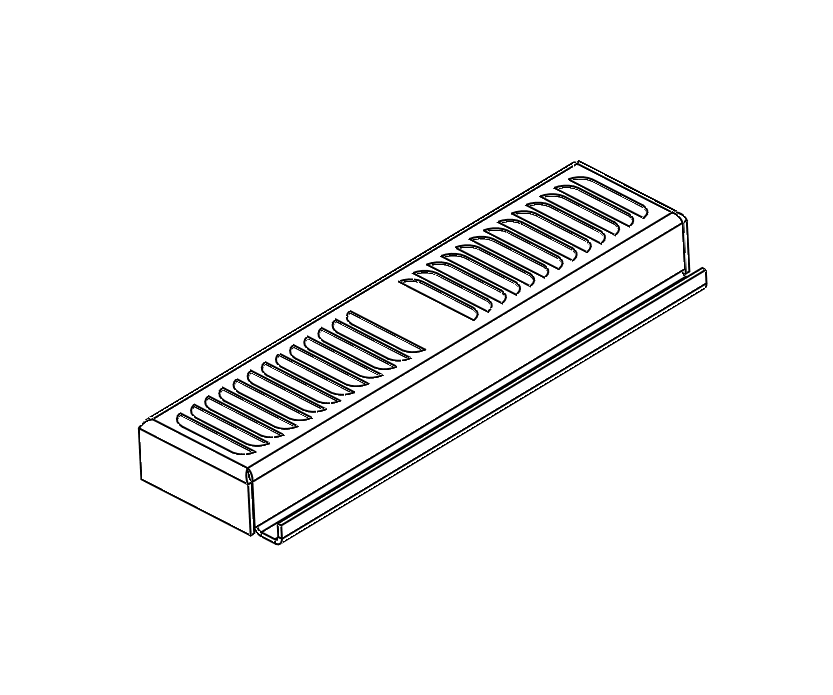

Aeration planks

-

The most important element of the floor ventilation system

-

Different designs for silos and flat warehouses:

-

Silo grilles are built to withstand the weight of the grain

-

Warehouse grilles are designed to support grain plus heavy machinery such as loaders, grain trucks, and trailers

-

Typical load capacity for flat warehouse planks: 10–16 tons per axle

-

Planks vary depending on the type of stored product:

-

Larger openings for coarse grains like corn, chickpeas, beans

-

For mixed storage, the smallest grain size determines the planks specification

Concrete Channels

-

The layout and type of channels in the concrete foundation are critical for proper ventilation

-

Channels are constructed during building phase based on a predefined scheme

-

SLAV-VERIGI Ltd., a leading manufacturer of grain ventilation systems, offers ready-made metal formworks for embedding in the floor:

-

Minimizes construction errors

-

Improves airflow

-

Simplifies cleaning and maintenance

Ventilators

-

Proper ventilator selection and installation is essential for system performance

-

SLAV-VERIGI’s engineering team provides expert guidance based on years of experience in grain and bulk product ventilation

Key Advantages of Active Floor Ventilation

-

Large ventilation opening area: 11% to 26% of total aeration surface of the planks

-

Ventilated floor coverage: from 15% up to 100% of silo or warehouse floor

-

Grille variety: perforated, elongated slots, framed or frameless – tailored to grain type

-

High load capacity: 7 to 16 tons per wheel – allows machinery to operate directly on top

-

Warehouse filling with vehicles: trucks, loaders, etc.

-

Easy cleaning: no upper edge to trap debris

-

Simple installation

-

Full control when combined with temperature monitoring systems

|

|

|