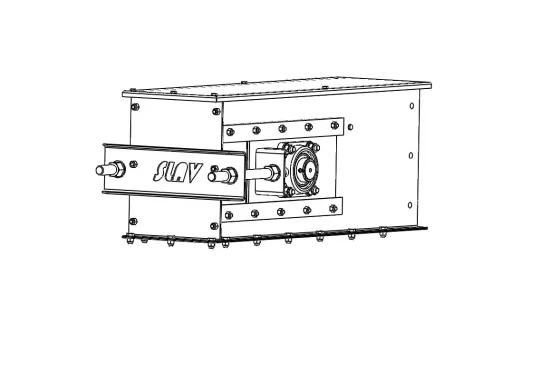

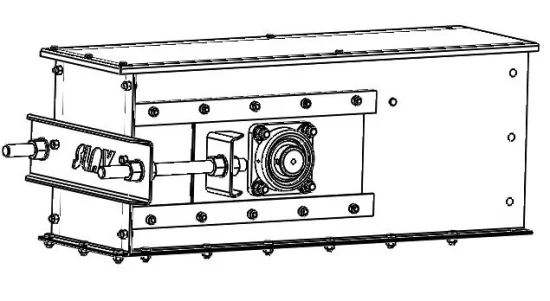

The tensioning station of the chain conveyor is a bolted structure made from hot-dip galvanized sheet metal with a thickness of 2.5–3 mm.

It serves to tension the chain of the machine, compensating for normal wear over time. Tensioning is carried out via two tensioning screws, applied evenly on both sides. The tensioning plates, with a thickness of 8 mm, are guided by four metal slides with polyethylene inserts. The flanged self-aligning bearings are dust-protected and manufactured by reputable brands such as LDK, SKF, FAG, or equivalent. The tensioning shaft and chain sprocket are made from high-quality carbon steels (not cast parts). A rotation monitoring sensor can be mounted on the tensioning shaft . |

2025, All rights reserved. Privacy policy