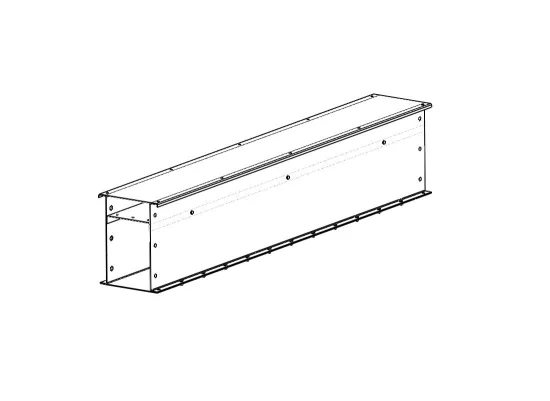

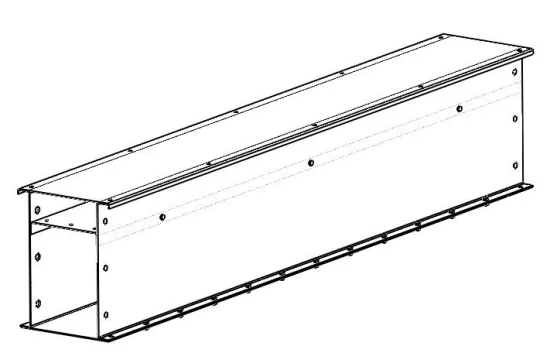

The intermediate sections (troughs) of chain conveyors are bolted structures made from hot-dip galvanized sheet steel. They consist of:

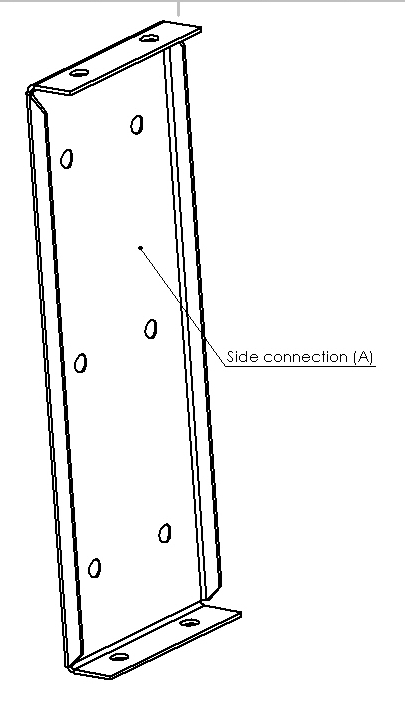

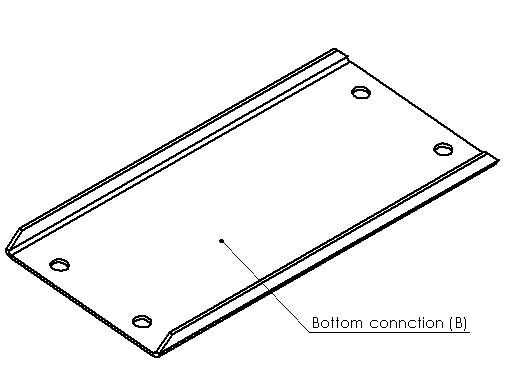

The bottom plate is the most wear-stressed part of the conveyor. Depending on the application, it can be manufactured with a thickness between 2.5 mm and 6 mm. For heavy-duty operations, it may be additionally reinforced with a layer of abrasion-resistant, anti-static, ultra-high molecular weight polyethylene (UHMW-PE1000). The side walls are made from galvanized sheet steel with a thickness of 2.5 mm. The cover is also made from galvanized sheet steel, with a thickness of 2 mm. When the machine is operated outdoors, the cover can be made with a dual-slope design to prevent water accumulation. Depending on the application, a double bottom or return rollers can be installed to support the return side of the chain. The troughs are standardly manufactured in lengths of 500 mm, 1500 mm, 2000 mm, and 3000 mm, and are connected to each other via side and bottom/top connections. |